Gantries for National Highways

6. Design concept illustration guidelines

Submissions are to provide illustrations of the gantry family with focus on the Cantilever and Super-span Cantilever variants. The following guidance provides the simplified requirements for the illustrations.

There is a range of current and future equipment that a gantry will be required to carry. This will be considered fully during the later technical design phase, but for visual clarity submissions will only need to include equipment described in this section.

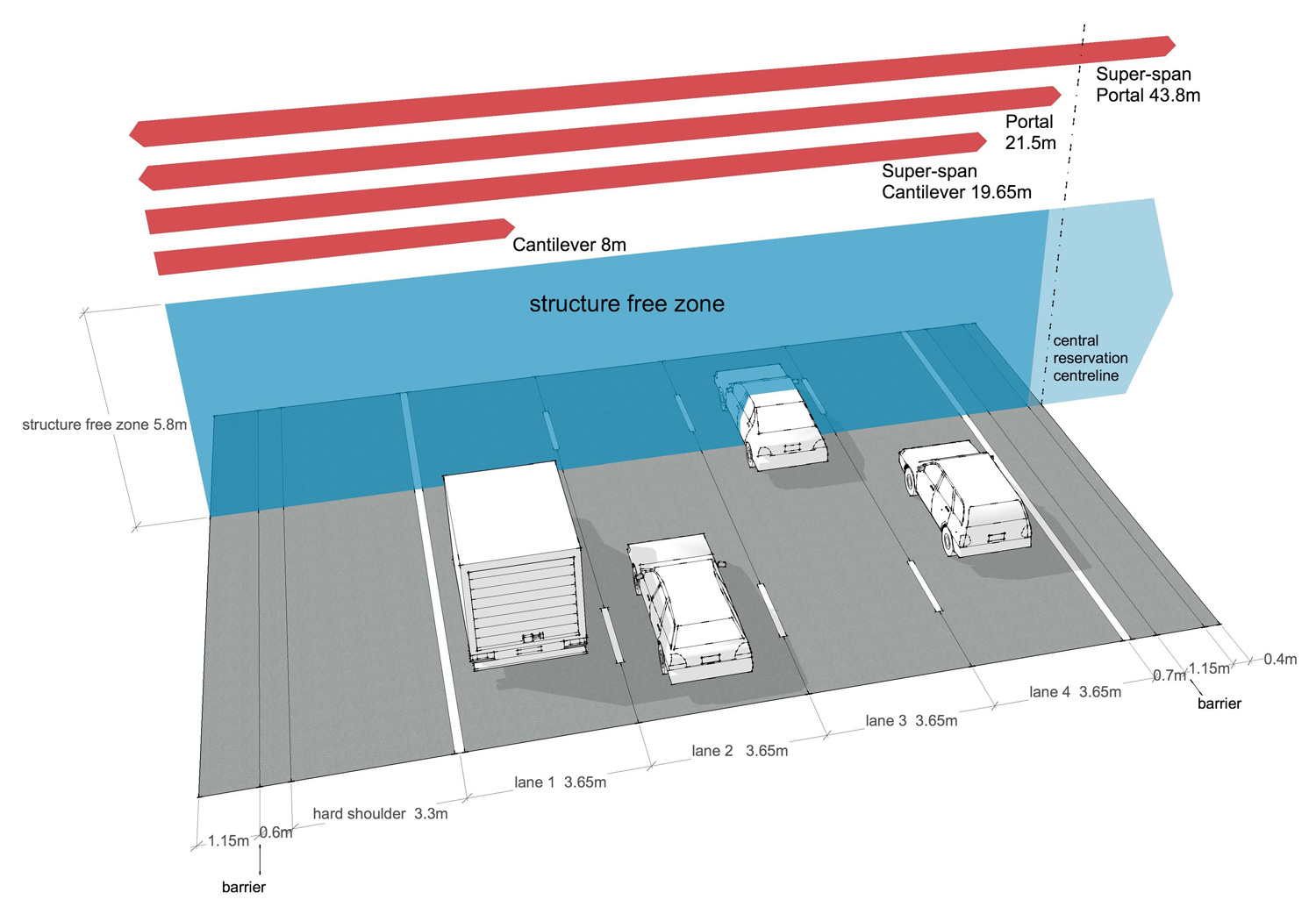

The following diagram describes the gantry and equipment constraints to be observed. Note that all of the gantry illustrations are maintenance accessible so will need to show a maintenance walkway (with minimum clear width of 0.6m and a preferred overhead clearance of not less than 2.1m, 1.5m minimum) with vertical protected access. Equipment or signs should be positioned such that they do not interfere with each other and offer unobstructed views to the road user.

These illustration guidelines are indicative only. Submissions will not be judged on the aesthetics or positions of ancillaries or backgrounds, only on gantry designs.

Whilst the required illustrations are to incorporate a 4-lane motorway with hard shoulder it is worth noting that working designs will need to accommodate a range of motorway and major road configurations and widths.

Cantilever gantry

6.1

Illustrations of the design concept are to include:

-

1. A single gantry mounted Variable Message Sign

(a large electronic information sign)

positioned with its centreline over lane 1. Its maximum dimensions are: 4.41m wide, 3.3m height, 0.5m deep.

1 -

2. A gantry mounted Speed Camera

one camera per lane, including hard shoulder, rear facing. Positioned at 5m height with a 2.75m to 4.25m horizontal distance from the structure free zone.

2 -

3. An array of 4 solar panels (photo voltaic)

mounted on the superstructure, typically inclined 30° to 40° from the horizontal to maximise solar capture, each 1.6m long, 1m wide.

3

All Other Gantries

6.2

Illustrations are to include:

-

1. A static sign

14m wide, 3m high (Super-span Cantilever example below) and,

1

-

2. Advanced Message Indicators (lane specific electronic signs)

One sign per lane, including hard shoulder, front facing, mounted above lane centreline (example below). The dimensions are: 1.84m wide, 1.5m height, 0.35m deep.

2 -

3. Include a gantry mounted Speed Camera

One camera per lane, including hard shoulder, rear facing. Positioned at 5m height with a 2.75m to 4.25m horizontal distance from the structure free zone.

3 -

4. An array of 4 solar panels (photo voltaic)

mounted on the superstructure, typically inclined 30° to 40° from the horizontal to maximise solar capture, each 1.6m long, 1m wide.

4

Further details of the submission requirements, deadline and method are provided in Section 16 to 17.

7. General design considerations

- Consideration should be given to efficient and economical overall construction processes that may, for example, explore the balance between offsite manufacturing/fabrication and on-site assembly/installation. Expected positive or negative impact of the design on costs should be identified alongside any efficiencies in construction, maintenance and dismantling.

- Operational constraints of the major road network, and minimising impact on users, should be considered in the installation, operation, maintenance and cleaning of the structures.

- Structural strength is important to ensure gantry integrity and longevity for a design life of 60 years. These critical features will be developed in the technical design phase but at this stage concepts should have the scope to be structurally feasible.

- In line with National Highways Net Zero commitments the reduction of embodied carbon is strongly encouraged.

- Material choice will be imperative to deliver structural integrity whilst minimising embodied carbon