1. Flat Base

Flat or near flat base to gasholder, i.e. effectively no dumpling

Gasholders were large storage vessels used to hold coal gas produced on a gasworks and more recently natural gas. The purpose of the gasholders was to act as a buffer allowing greater operational flexibility - they allowed for additional supply during high peak demand. Due to improved technology allowing storage of gas within the below ground mains network, gasholders are no longer used for gas storage and National Grid are undertaking a programme of decommissioning and dismantling.

The type of gasholder relevant to this competition is a telescopic above ground steel vessel above a below ground water filled tank.

The gasholder consisted of a telescopic above ground steel vessel which was sealed at the top and open at the base. The rising of the gasholder was guided either by external columns or by spiral rails on the inside or outside of the steel vessel. The water filled gasholder base acted as a seal to prevent gas escaping and was constructed from brick, stone or concrete, iron, steel, bedrock or a combination of these. Figure 1 below presents a typical cross section of a gasholder showing the above ground columns and steel vessel on the left and the internal support structure and below ground tank on the right.

Figure 1

Typical cross section with above and below ground gasholder structures

Because brick or stone tanks were porous, the tank was waterproofed to prevent water leakage and generally surrounded by puddle clay on the outside of the wall and beneath the base. The puddle clay could be pure clay, but it was thought preferable to mix clay with one-third sand, silt, or soil free from plant matter. An alternative method of waterproofing was through the application of Portland cement render to the internal face of the tank. If applied, such tanks would not necessarily require puddle clay. Latterly, the tank itself was built from waterproof concrete and therefore did not require rendering or puddle clay lining.

Depending on the ground conditions, rather than excavating all the material out to form the base, it was more economical to leave a conical mound with a flat top within the centre of the gasholder tank referred to as a 'dumpling'. Where the bedrock was shallow and competent, tank bases were formed by cutting a circular annulus into the bedrock to form a channel which contained the water. The size of the dumpling depended on the ground conditions with larger dumplings present at sites where the underlying geology allowed for greater angles of repose (e.g. drained clay allows a greater angle of repose than wet clay and therefore would allow a steeper and thus larger dumpling). Therefore, dumplings shapes and sizes varied on a site by site basis.

For the purpose of this competition please consider water filled gasholders where the tank base is below ground. The gasholders will have been decommissioned and the above and below ground metal structures removed. The water within the gasholder base will have been removed and any residual sludge in the base of the holders will have been removed including sludge on the base and walls. Designs idea that attempt to re-use the metal columns will not be considered since the columns will, in all cases, have been removed during demolition.

Further information on gasholders is provided in "Gasholders and their tanks", a Gasworks Profile document written by Russell Thomas in 2014

Photo 1:

Brick lined, low dumpling

Photo 2:

Concrete base with no dumpling

The base of the tank/dumpling may be formed of bare rock but this is unusual due to the need to seal the tank against ingress/egress of water. There is usually a puddle, clay lining which may be further covered with a layer of brick, stone or concrete, although exposed clay is not uncommon. Later tanks were often formed of structural concrete which usually extended across the base or around the dumpling.

There are potentially three different scenarios in terms of dumpling geometry:

For flat or near flat bases with a negligible dumpling, it is considered that little or no re-profiling of the base would be required with any level changes taken into account by a hard-core layer below the floor slab. Where a dumpling is present on a soft base, re-profiling is considered appropriate to optimise the maximum void space. However, if a reduced void space is considered acceptable, then minor infilling of the holder annulus around the dumpling could be undertaken to achieve a level surface. This would also be the solution where the base is located directly on bedrock and re-profiling of the bedrock would be difficult and expensive.

The main risks associated with redeveloping holder bases are:

The main opportunities are:

A roof over all the gasholder base will be required to prevent rainwater ingress and allow above ground drainage of any collected rainwater. Any rainwater that enters the gasholder base will need to be pumped up and out of the holder.

There are many roof options, some of which require internal support, while others do not. Protrusion above ground should not be an issue because the former use as a gasholder will have dominated the local skyline and can be used as precedent within the planning system. For most developments, some sort of natural light would be advantageous, with glazing forming part of the roof. Some uses such as secure storage may not require natural light.

A domed roof will closely match the previous gasholder form and may be in keeping for redevelopment within sensitive historical areas. A simple portal roof may be cost effective, but the larger the span, the greater the engineering (and cost) and may require a central support if the holder is greater than 30m in diameter. A flat roof potentially allows space for additional useable area, but will require support from below. Support would need to be considerable (and expensive) in order support any sort of load (greenspace, car parking etc).

The potential internal arrangements are infinite and categorised into two:

In either situation, the useable space will need to be well lit unless the roof allows in sufficient natural light and there are void spaces down through the structure to allow light wells to penetrate to the bottom of the gasholder.

Consideration has been given to potential redevelopment options and should be applicable to all gasholders throughout the country.

Of note is that options such as climbing wall, shooting range, trampoline park, are all assumed to be covered under Sports Centre. All options that require no or little investment are potentially unattractive to National Grid because of the risk that the purchaser may subsequently fail financially with the site then potentially becoming a health and safety problem or eyesore that reflects badly on National Grid because of its historical association with the site. Business, Institutional or public organisations with good covenant strength are preferred purchasers.

Also noteworthy is the general presence of good utility connections at these sites. Gas, water and electricity are always present due to the nature of previous operations. Many of these sites have sub-stations within or close to the site boundary due to utility operators historically sharing land resources. Sewer pipes are always present for site staff and holder water discharge.

Possible options could be for office, storage, accommodation, retail, event space, sports, health or education. However the options are extensive and National Grid are looking for innovative solutions for future uses.

For the purpose of this competition four sites have been identified and competitors are requested to create their design for one site option at this stage. Not all the holder bases on a particular site have to be used, but if they are not used, they will need to be shown as managed or filled, to prevent the holder base becoming filled with water and a subsequent health and safety hazard. In summary, a design using just one holder is acceptable, but please indicate how the other holders on a site will be developed (backfilled or managed). Please note that the 'missing' gasholder numbers are due to the fact that some of the sites were part of larger gasworks and/or previous holders have been demolished and replaced by current gasholders. The numbers provided tie-in with the dimension tables.

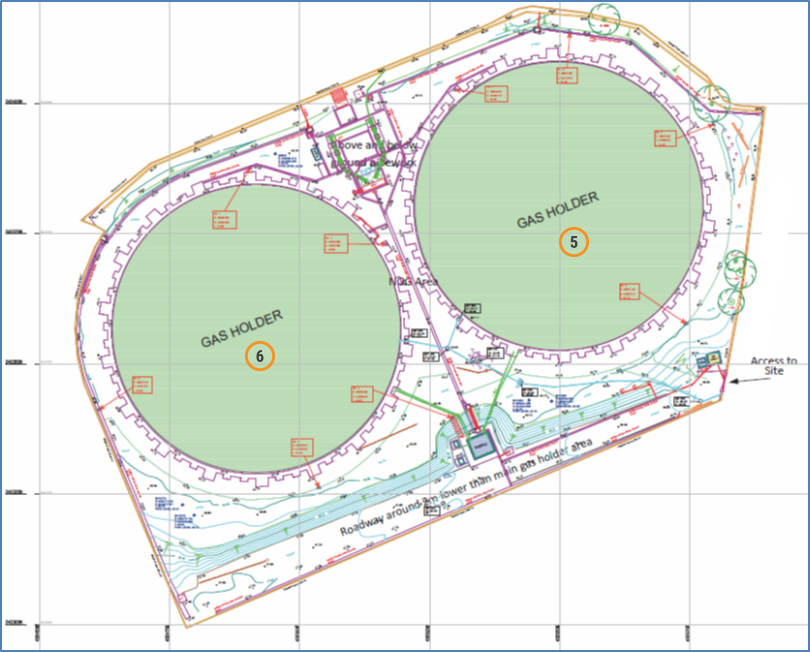

The site contains two underground gas holders and is:

The holder dimensions are shown below.

| Gasholder | Tank Construction | Diameter (m) | Maximum depth (mbgl) | Minimum Dumpling depth (mbgl) |

|---|---|---|---|---|

| Gasholder No. 5 | Masonry | 56 | 11.28 | 9.39 |

| Gasholder No. 6 | Masonry | 56 | 12.52 | 9.51 |

This site contains six underground holders, and benefits from a large area of available land to the east and north that could be developed at the same time. The site setting is:

The holder dimensions are shown below.

| Gasholder | Tank Construction | Diameter (m) | Maximum depth (mbgl) | Minimum Dumpling depth (mbgl) |

|---|---|---|---|---|

| Gasholder No. 1 | Masonry and concrete | 43.4 | 11.76 | 11.16 |

| Gasholder No. 2 | Masonry and concrete | 43.4 | 11.82 | 11.1 |

| Gasholder No. 5 | Masonry | 50.9 | 9.81 | 6.49 |

| Gasholder No. 6 | Masonry and concrete | 51.1 | 12.08 | 6.65 |

| Gasholder No. 7 | Masonry | 55.6 | 9.77 | 8.22 |

| Gasholder No. 8 | Masonry and concrete | 55.6 | 12.24 | 8.69 |

The top of the two middle holder bases are level with typical ground levels on-site, which is relatively flat The two northern and two southern gasholder bases have been extended with a concrete skirt around the base, which is now approximately 1.5m above surrounding ground level.

The site covers an area of approximately 0.81 hectares and is in an area of mixed residential and light industrial land use, with open space directly to the west. Access to the site is gained via double chain link gates. The site is occupied by four gas holders and small buildings, plus a microwave telecommunications mast in the northwest corner of the site. There is an electrical substation in the west of the site. Residential dwellings are to the east, south and west, with light industrial north and west.

The site is ~3 km from the city centre and 3.2 km from a large estuarine river.

The holder dimensions are shown below.

| Gasholder | Tank Construction | Diameter (m) | Maximum depth (mbgl) | Minimum Dumpling depth (mbgl) |

|---|---|---|---|---|

| Gasholder No. 1 | Masonry | 32.6 | 8.73 | 7.35 |

| Gasholder No. 2 | Masonry | 32.7 | 8.68 | 8.44 |

| Gasholder No. 3 | Masonry | 32.6 | 8.61 | 7.46 |

| Gasholder No. 4 | Masonry | 32.7 | 8.44 | 8.35 |

The top of the holder bases are level with typical ground levels on-site. The site is flat.

This site has two very large holders that present additional opportunities, ~2 km from a major city centre next to a major road connection. The site is in a mainly industrial area, although there are offices to the west and a large residential area to the east.

The holder dimensions are shown below.

| Gasholder | Tank Construction | Diameter (m) | Maximum depth (mbgl) | Minimum Dumpling depth (mbgl) |

|---|---|---|---|---|

| Gasholder No. 12 | Masonry | 57 | 10.97 | 1.2 |

| Gasholder No. 13 | Masonry | 70.1 | 15.24 | Assume 12.0 |

| Gasholder No. 14 | Masonry | 70.1 | 15.24 | Assume 12.0 |

The north of the site is elevated in comparison to the roads running around the site, with big retaining walls forming the boundary. While current access is through the neighbouring manned security gate, there is potential to engineer direct access into the northerly gas holder base from street level.

The two large gasholders share a column where they intersect, so connecting the two holders should also be relatively straightforward, if required.

The site of interest is shaded blue in the site plan below.

Below-ground gasholder bases offer a unique opportunity for iconic and cost-effective redevelopment. National Grid hope that this competition will generate a variety of exciting and innovative design proposals for their future redevelopment.

The competition is being managed and administered by RIBA Competitions on behalf of National Grid. All enquiries relating to the competition should be directed to:

0113 203 1490